Solar energy production is growing exponentially worldwide, driven by the need to transition to renewable energy sources. However, the efficiency and profitability of photovoltaic installations largely depend on their proper operation and regular maintenance. It is in this context that drone thermal mapping has emerged as a revolutionary technology for fault detection on photovoltaic production sites. This innovative method allows for rapid, accurate and cost-effective inspection of large solar panel fields, providing site managers with a detailed view of the status of their installations.

Drone thermal mapping relies on the use of thermal cameras on specially equipped drones. These cameras capture infrared radiation emitted by solar panels, allowing temperature variations on their surface to be visualized. Healthy solar cells have a uniform temperature, while defective areas appear as hot or cold spots on thermal images.

One of the main advantages of this technology is its ability to cover large areas in record time. Where a manual inspection on the ground would take days or even weeks, a drone can fly over and map an entire solar field in just a few hours. This speed of execution not only reduces inspection costs, but also increases the frequency of inspections, thus promoting early detection of problems.

Another major advantage of drone thermal mapping is the accuracy of the data collected. High-resolution thermal cameras can detect minute temperature variations, revealing defects invisible to the naked eye. This sensitivity allows for the identification of a wide range of problems, from micro-cracks in cells to electrical connection faults, shading or soiling issues.

In addition, drone thermal mapping provides an overview of the installation, allowing the identification of recurring fault patterns or large-scale problem areas. This global perspective is particularly valuable for maintenance optimization and intervention planning.

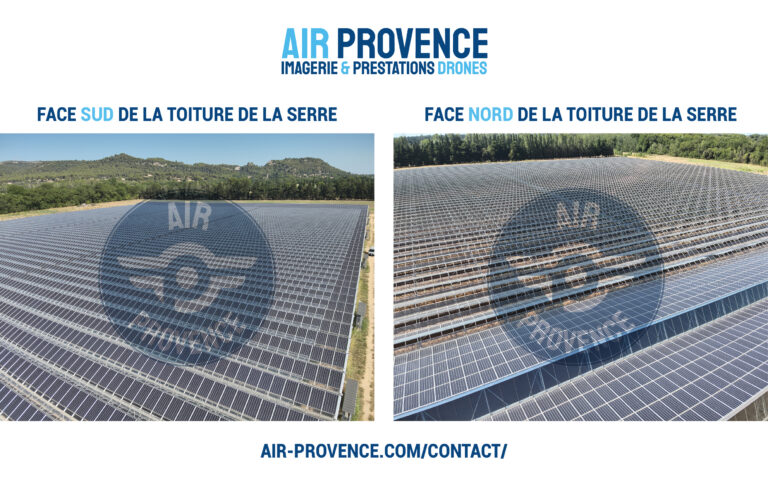

Example of a photovoltaic greenhouse:

To ensure the reliability and relevance of the data collected, drone thermal mapping must comply with specific parameters and methodologies. One of the crucial factors is the solar irradiance level at the time of inspection. According to industry standards, including the IEC standard, a minimum irradiance of 600 W/m² is recommended to obtain meaningful results.

This requirement usually involves conducting inspection flights around solar noon, when sunlight is at its peak. Flight planning is also crucial for the quality of the data collected. Drone trajectories must be carefully programmed to ensure complete and uniform coverage of the facility, with sufficient overlap between images to allow their subsequent assembly into a coherent thermal map. The flight height must be optimized to offer the best compromise between image resolution and surface area covered.

The choice of equipment is crucial. The drones used must be stable, capable of following precise trajectories and equipped with advanced geolocation systems. Thermal imaging cameras must provide sufficient resolution and thermal sensitivity to detect even the most subtle anomalies. Increasingly, these drones are also equipped with high-resolution RGB cameras, allowing thermal and visual images to be superimposed for a more comprehensive analysis.

Processing the collected data is a key step in the process. Specialized software is used to assemble the thermal images into a coherent map, correct geometric and radiometric distortions, and apply automatic anomaly detection algorithms. These tools make it possible to generate detailed reports, precisely identifying the location and nature of the detected defects.

VISIBLE + THERMAL CAPTURES

The adoption of drone thermal mapping has a significant impact on the operational efficiency of photovoltaic production sites. By enabling early and accurate fault detection, this technology helps reduce downtime and optimize energy production. Site managers can prioritize maintenance interventions based on the severity and extent of the identified issues, thus maximizing the return on investment of their installations.

Beyond simple fault detection, the data collected by thermal mapping offers a wealth of valuable information for analyzing the long-term performance of installations. By comparing heat maps over time, it becomes possible to track the evolution of the state of the panels, identify degradation trends and anticipate future maintenance or replacement needs.

The integration of artificial intelligence and machine learning into the thermal data analysis process opens up new perspectives. These technologies can automate anomaly detection, improve diagnostic accuracy, and even predict future failures based on observed patterns.

In the future, we can expect to see even deeper integration of drone thermal mapping into PV plant management systems. Continuous monitoring solutions using autonomous drones that can perform regular inspections without human intervention are already in development. These systems promise to further optimize the maintenance and performance of solar plants.

Drone thermal mapping is emerging as an essential tool to ensure the efficiency and profitability of large-scale PV plants. By combining speed, accuracy, and comprehensiveness, this technology is revolutionizing the way faults are detected and managed in the solar industry. As the sector continues to grow and evolve, the importance of such innovative solutions will only increase, contributing to the continued optimization of solar energy production worldwide.

Several French departments have installed photovoltaic power plants. Among the most notable, we can mention Landes, which stands out as the department with the largest number of solar installations. Haute-Garonne comes in second, closely followed by Isère.

Other departments in the south of France also stand out with significant installed capacities, notably Hérault and Bouches-du-Rhône.

In the north of the country, more industrial departments such as Nord, Loire-Atlantique and Rhône are experiencing significant growth in terms of installed solar capacity.

Essonne, in Île-de-France, is also mentioned as an example of a department that has developed solar installations.

It is important to note that the distribution of photovoltaic installations in France is not uniform and is mainly concentrated in the southern regions, which benefit from more favorable sunshine. The regions of Nouvelle-Aquitaine, Occitanie, Provence-Alpes-Côte d’Azur and Auvergne-Rhône-Alpes are particularly well equipped in terms of solar capacity.

However, it is interesting to note that some departments that are highly equipped with solar panels, such as Landes, Haute-Garonne and Isère, are not among the sunniest in France, which suggests that factors other than sunshine influence the development of photovoltaic installations.

AIR PROVENCE is a company from the Provence-Alpes-Côte d’Azur (PACA) region, based in Toulon (83000 Var). Led by Augustin Navarranne, who is also an experienced drone pilot, it offers aerial imaging services by drone for a diverse clientele, including photovoltaic panel inspections.

Thanks to their technical expertise and experience in the use of drones, Air Provence is able to carry out photovoltaic panel inspections using high-resolution cameras and thermography. Drones allow solar panels to be inspected at height without the need for a nacelle or lifting equipment, making the inspection more efficient and less expensive.

Using Air Provence for a photovoltaic panel inspection by drone can offer advantages such as flexibility, safety, time savings and cost. With their head office located in Toulon, Air Provence is ideally located to meet the needs for photovoltaic panel inspections by drone in the PACA region and beyond.